While IIoT deployments can deliver considerable value, less-successful IIoT initiatives are burdened with data silos that ultimately result in suboptimal industrial performance.

The Industrial Internet of Things (IIoT) is gaining considerable traction, with new platforms appearing almost weekly and numerous companies implementing IIoT projects. But are the companies really getting the full value from them? The simple answer is sometimes, but usually when targeting specific problems, the bigger picture is more complex, and the results are often not as impressive.

One particular hurdle is that data silos can plague IIoT projects, in turn causing operational problems and degraded decision making. This article takes a closer look at this phenomenon and how to avoid it when implementing IIoT.

Why should you care?

Have you ever suffered from delayed or potentially incorrect decisions? Not easy to quantify, but I am sure we can all think of anecdotes where isolated data was not readily available or not reviewed, which then led to machine failure, downtime, etc.

One example I came across was where an external company had been employed to analyze some bearings, however, the report was not reviewed in a timely manner, one of the bearings failed and a $10,000 maintenance item suddenly became $250,000 of lost production and repairs.

In your company, how much is each hour of downtime worth?

Another aspect to consider is the waste of time trying to find information — studies have quantified that this can be anything from 1.8 to 2.5 hours per day (see this article for more info).

This is hours per day lost due to not having the information you need to make decisions. Let’s think of those numbers in production terms. What is the value of 20–25% of your production? That is what you could be losing every day. Did that get your attention?

Beyond that, data silos lead to duplication of effort, lack of synergy and missed opportunities.

Are those reasons good enough to make you think more about avoiding data silos?

How do Data Silos manifest themselves across organizations?

Sometimes it can be difficult to know whether you are suffering from this problem. So, let’s explore the symptoms:

- Blurred Vision – Are you having trouble getting a clear picture of the problem? Think of it like eyeglasses with the wrong prescription. You can see a bit but your vision might be blurred. Data Silos have a similar impact.

- Less Informed Decision Making – Do you have the full picture? Are you missing some of the pieces of the jigsaw? This impacts your decision making and can lead to bad decisions.

- Deceleration – Are you feeling the drag of data preparation? Is it slowing you down? How much time is needed to get at data? Is it difficult to bring diverse data sources together?

If you are trying to diagnose an operational problem and are spending too much time trying to get access to the right data or the data is in separate repositories that cannot easily be connected, then you have a problem.

It’s also worth making mention of the opposite problem. More data does not necessarily lead to more productivity. A data lake might sound like a good idea, but what happens when you end up with a data swamp? The issue in this scenario is that you often cannot see the wood for the trees.

What are Data Silos?

Operational Data Silos occur when the data you need to make decisions is scattered across different locations, some may be on your operational network, some might be on your business network.

For example:

- Operational data: SCADA, PLCs, DCS, Vibration data, data historians

- Business data: ERP, Supply Chain information

- Other: Supplier held information

- New: IIoT data

You can often end up with data that is splintered into application or departmental data stores, that for practical purposes are unavailable.

A good example that most of you will be familiar with is vibration data where historically a company hires an external vendor to come in, take readings, analyse and provide a report. The data is held separately by the vendor it is not embedded in your existing data historian, where alerts can be automatically generated, and not available to be used as part of other analysis. A classic data silo that can lead to problems.

What causes Data Silos?

Generally speaking there are four main

causes of Data Silos:

(from HBR: Breaking Down Data Silos by Edd Wilder-James)

- Structural (your IT or Data architecture) – Is your design flawed and causing silos?

- Political (the natural desire to hoard) – Are departments protecting their own data?

- Growth (moving too fast to keep everything straight) – Is fast, organic growth hurting you?

- Vendor lock-in (proprietary technology) – Are vendors building walls around your data?

Why is IIoT making this worse?

IIoT is relatively young with new platforms coming onto the market on an almost weekly basis. As most technology companies will tell you, it’s a lot simpler and quicker to build a standalone tool than one that integrates with everything else. Then on top of that, in order to provide the necessary performance, many are using proprietary databases.

So, what is happening is that companies are selecting best-in-class IIoT platforms, with a focus on solving specific problems.

Many of the IIoT platforms selected are proprietary and not designed to interconnect with other platforms or existing Industrial data historians, such as OSIsoft PI.

This then results in new silos of data.

The energy industry is already struggling with this problem. Intelligent Meters, Smart Grid devices and Micro-Generation are becoming increasingly common and are causing multiple data silos that unless addressed will result in considerable future issues.

It is not all doom and gloom though, some of the long-established players in the operational space are becoming IIoT platforms in their own right and helping to bring together the traditional data sources with the new. For example, OSIsoft’s PI System has been recently ranked higher than comparable systems from GE, PTC and others in the annual PAC RADAR on IoT Platforms for Industrial Applications in Europe (Download the full report here).

Industry 4.0 + IIoT = Competitive Advantage

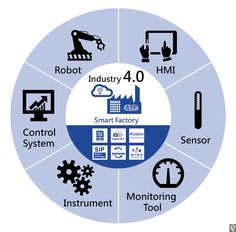

As we have established, Data Silos are causing considerable loss of business performance. The macro view of the situation provides even greater opportunities with access to your operational data being key to enable an Industry 4.0 Strategy.

Industry 4.0, the fourth industrial revolution, is a philosophy or a corporate approach that takes this bigger picture into account. When combined with enabling technologies such as IIoT it will truly generate competitive advantage.

IIoT technology alone will not generate the expected return on investment, it needs to be part of a bigger strategy.

PREVENTING DATA SILOS

A holistic view of your tools, data and architecture, including IIoT are key to success.

Start by developing a truly cross-functional Industrial data strategy and architecture that brings together all the necessary pieces and provides one source for all your industrial data, plus provides interconnection to other information to provide context, for example, ERP data such as the SKU being produced.

IIoT needs to be part of your architecture, not an add-on or afterthought.

In summary:

- Be clear on what you are trying to achieve

- Define your Data Architecture up-front

- Select products that can co-exist

- Plan for integration

SUCCEEDING WITH IIOT

The chart below provides some simple but important steps to achieving success with IIoT.

It starts by being clear in what you are trying to achieve and obtaining executive sponsorship. Without these initial steps your chances of success are limited.

Next define your data architecture and ensure you understand how both operational and business data will co-exist and interact. This again is critical to the longer-term success.

Break your project into manageable chunks, think agile approaches, small projects that deliver value, and as far as possible make the projects cross-functional in nature. Try to avoid projects focused on a single area, otherwise there is a risk of creating new data silos.

Lastly, ensure you have a good change management plan on how you will implement the tools and ensure that appropriate data is used to measure the results (for more on Change Management).

I cannot emphasise enough how important Change Management is to success – without it you will be wasting your time and money!

Michael Kanellos (IoT Analyst) and I recently did a webinar discussing this very key topic, and I would recommend it for those thinking of deploying IIoT solutions.

For more on this please click this link for:

- Webinar recording (Nov 2019)

- Presentation deck

Good luck with your IIoT projects!

If you need assistance with your IIoT or your Industry 4.0 Strategy then please contact us to discuss further, thank you.